When many people hear the words “screen printing” or “silk printing” they automatically think of printing on a t-shirt, but screen printing can be used on substrates ranging from metal to plastic. Screen printing is best for graphic, designs. One printing technique is particularly suited to a flat or relatively flat surface. The process involves a screen or fine mesh stretched tightly around a T-shirts bedrucken frame, which is a ridge. Areas that you do not want to print are hidden on the print screen. To create the print, the framed screen with a blob of thick ink is positioned over the item to be printed. To push the ink through the screen you would use a squeegee. A stiff rubber blade is mounted on a plastic or wooden handle. It is used to pull the pain across the screen to push the ink through the screen.

Prevented from passing through

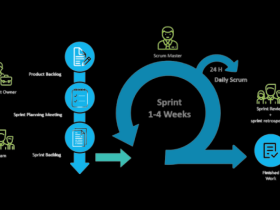

In the masked areas the ink is prevented from passing through, but in the unmasked areas the connection can be printed. Once this is done, the item is placed through the heat tunnel on a conveyor belt. This is called the curing process to ensure the inks dry quickly so the material can be wrapped or stacked. When properly cured, the inks will stay on the printed substrate even under harsh conditions. If additional colors are desired in the final design, the process is repeated using the different screens. For example, if the design calls for three colors, three different screens would be required.

To ensure the colors are registered or properly aligned, the screens are typically placed on a rotary press. Some screen printers have fully automatic presses. With these types, no manual work is required apart from setting up the machines and then loading and unloading the machines.

A screen can be masked in many different ways

Applying masking fluid directly to the screen is the easiest way. This way you can just print a graphic or two. For a more complex print, it is ineffective. Screen printers often use light-sensitive emulsions for multicolor jobs. The first step is to on a clear plastic file. Next, a photosensitive coating is applied to the entire screen surface. After drying, the film is placed on the screen and then exposed to bright light. After some time, the screen printer washes the exposed areas off the screen with water. Now the screen is ready to print. When you print on a dark color, a white primer is applied first.

T-Shirt Printing – Direct

Printing t-shirts with Direct To Garment (DTG) printing, the process of printing cotton-based fabrics (e.g. t-shirts) using a large format Inkjet printers are vastly superior to screen printing, the process of forcing ink through a stencil into fabric. It is more environmentally friendly, less time-consuming and cheaper for smaller runs.

DTG T-shirt printing is more environmentally friendly than screen printing. DTG uses water-based inks to print directly onto clothing. This means that there is no excess ink used in the actual printing and the only waste produced is from the occasional cleaning of the printhead – it should also be noted that not all external materials contain only ink. Of course, regular printer maintenance can avoid major head cleaning, and so one head cleaning per day – a matter of milliliters – is usually sufficient. As long as the waste ink is properly disposed of, printing t-shirts using the DTG process should have almost no environmental impact. However, screen printing has excess ink from parts of the stencil that will not be printed onto the T-shirt, and when screens are cleaned these excess inks are then flushed down the drain.

Leave a Reply